Phambili kwibhola yegroove enzulu

Inkcazo yevidiyo

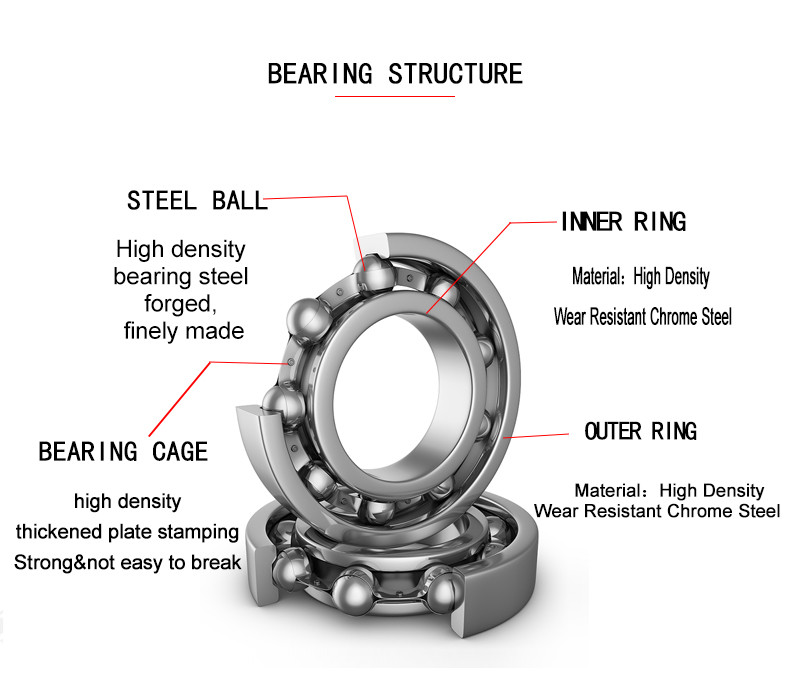

Isakhiwo sokuthwala

I-deep groove ball bearing inesakhiwo esilula kwaye kulula ukufezekisa ukuchaneka okuphezulu kwemveliso xa kuthelekiswa nezinye iintlobo, ngoko ke kulungele ukuveliswa kobuninzi kwiichungechunge, kwaye indleko yokuvelisa iphantsi, ngoko ithandwa kakhulu ekusebenziseni.Ukongeza kuhlobo olusisiseko, kukho izinto ezahlukeneyo ezakhiweyo, ezinje: ibhola yegroove enzulu enegquma lothuli, ibhola yegroove enzulu ephethe umsesane wokutywina werabha, ibhola yegroove enzulu ene-stop groove, ibhola yegroove enzulu enomthwalo omkhulu. inotshi yebhola, umqolo ophindwe kabini oqulathe ibhola enzulu.

Inzuzo yethu

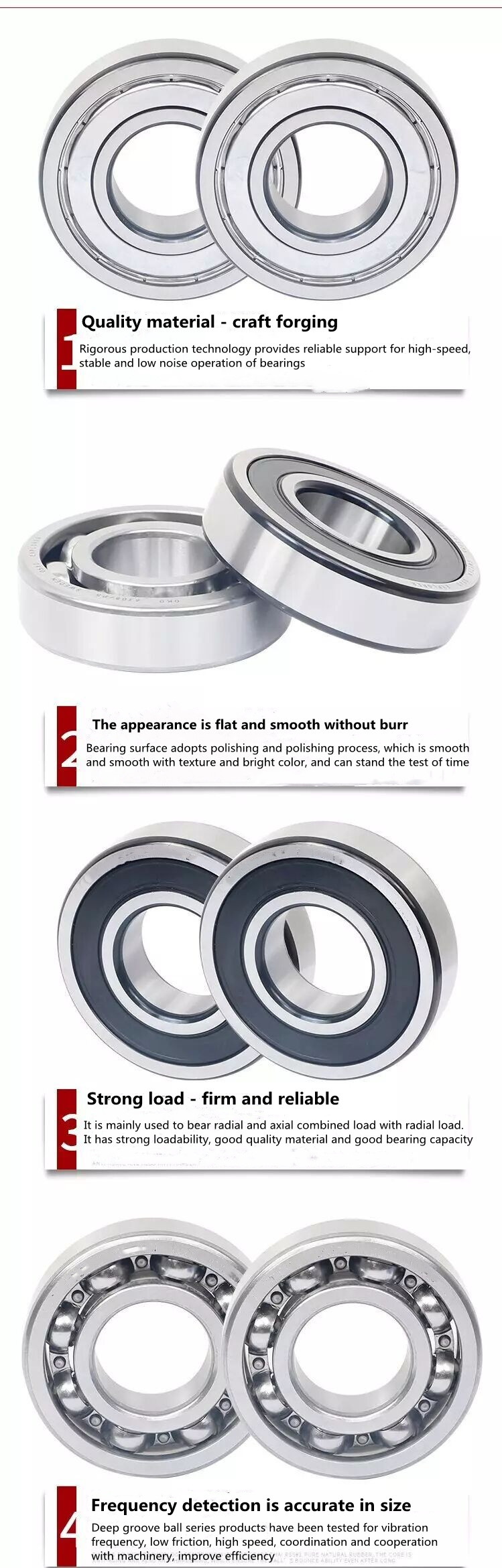

I-1, ukukhutshwa kwe-radial kuncinci, i-centripetal ye-angular yoqhagamshelwano inokulayishwa kwangaphambili amandla akhoyo alayishwe kwangaphambili ukuphelisa ukukhutshwa, ukuchaneka okuphezulu kokusebenza;

2. Phantsi kweemeko eziqhelekileyo, ukusebenza kakuhle kweebheringi eziqengqelekayo zilingana naleyo ye-hydrodynamic lubricated bearings, kodwa iphezulu kuneebheringi ezixutyiweyo;

I-3, ngenxa yobukhulu obufanayo bobubanzi be-shaft, ububanzi be-rolling bearing buncinci kune-sliding bearing, enokwenza isakhiwo se-axial somatshini sidibanise;

4. Iqondo eliphezulu lokulinganisa, ukuveliswa kwe-batch, ukusetyenziswa kwe-lubricant encinci, ukutywinwa okulula, ukugcinwa lula, akukho mfuneko yentsimbi eluncedo engenazo i-ferrous kunye neendleko eziphantsi.

Umboniso wemveliso

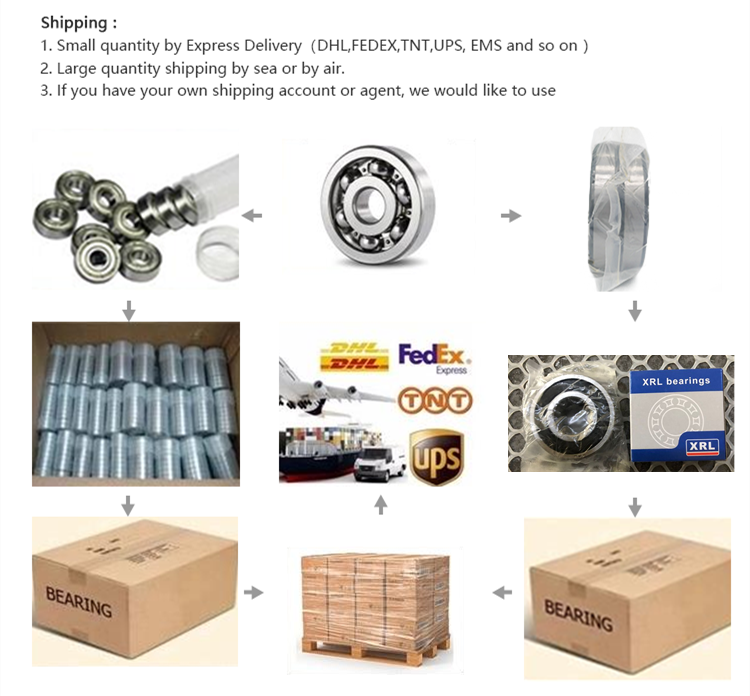

Ukuhambisa ngenqanawe

Isicelo

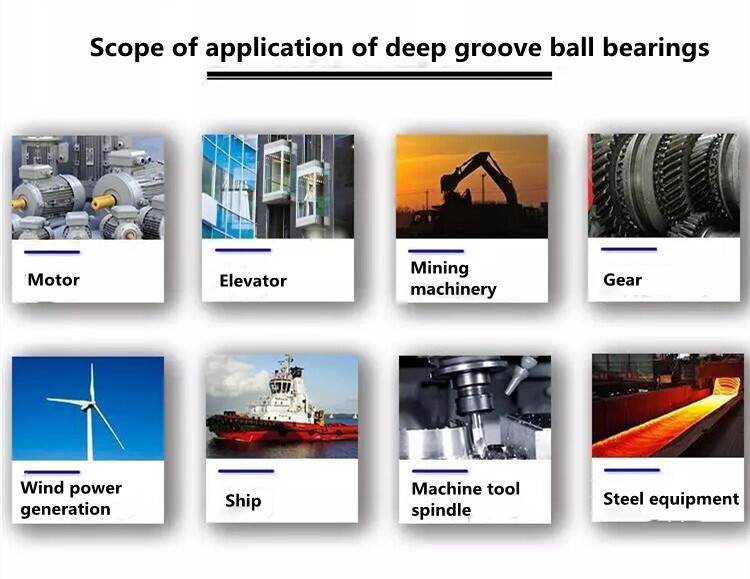

Iibhodi zebhola ze-groove ezinzulu zinokusetyenziswa kwiibhokisi zegiya, izixhobo kunye neemitha, iimoto, izixhobo zasendlini, iinjini zokutsha zangaphakathi, izithuthi zendlela, oomatshini bezolimo, oomatshini bokwakha, oomatshini bobunjineli, i-roller type roller skates, yo-yo, njl.

Iiparamitha

| Ukubamba inombolo. | Imilinganiselo (mm) | Umlinganiselo womthwalo (KN) | Ubunzima(kg) | |||||||

| d | D | B | rmin | r1min | Dynamic Cr | I-Static Kor | ||||

| 6403 | 17 | 62 | 17 | 1.1 | 0.5 | 22..500 | 10.800 | 0.2680 | ||

| 6404 | 20 | 72 | 19 | 1.1 | 0.5 | 31.000 | 15.200 | 0.4000 | ||

| 6405 | 25 | 80 | 21 | 1.5 | 0.5 | 38.200 | 19.200 | 0.5290 | ||

| 6406 | 30 | 90 | 23 | 1.5 | 0.5 | 47.500 | 24.500 | 0.7100 | ||

| 6407 | 35 | 100 | 25 | 1.5 | 0.5 | 56.800 | 29.500 | 0.9260 | ||

| 6408 | 40 | 110 | 27 | 2.0 | 0.5 | 65.500 | 37.500 | 1.2210 | ||

| 6409 | 45 | 120 | 29 | 2.0 | 0.5 | 77.500 | 45.500 | 1.5210 | ||

| 6410 | 50 | 130 | 31 | 2.1 | 0.5 | 92.200 | 55.200 | 1.8550 | ||

| 6411 | 55 | 140 | 33 | 2.1 | 0.5 | 100.60 | 62.500 | 2.3160 | ||

| 6412 | 60 | 150 | 35 | 2.1 | 0.5 | 109.10 | 70.000 | 2.8110 | ||

| 6413 | 65 | 160 | 37 | 2.1 | 0.5 | 118.14 | 78.570 | 3.3420 | ||

| 6414 | 70 | 180 | 42 | 3.0 | 0.5 | 139.50 | 99.560 | 4.8960 | ||

| 6415 | 75 | 190 | 45 | 3.0 | 0.5 | 153.78 | 114.32 | 5.7390 | ||

| 6416 | 80 | 200 | 48 | 3.0 | 0.5 | 163.22 | 124.55 | 6.7520 | ||

| 6417 | 85 | 210 | 52 | 4.0 | 174.90 | 137.49 | 7.9330 | |||

| 6418 | 90 | 225 | 54 | 4.0 | 192.48 | 157.63 | 9.5650 | |||

| 6419 | 95 | 240 | 55 | 4.0 | 206.00 | 171.00 | 11.200 | |||

| 6420 | 100 | 250 | 58 | 4.0 | 223.08 | 194.61 | 12.904 | |||

| 6300 | 10 | 35 | 11 | 0.6 | 0.5 | 7.6500 | 3.4700 | 0.053 | ||

| 6301 | 12 | 37 | 12 | 1.0 | 0.5 | 9.7200 | 5.0900 | 0.057 | ||

| 6302 | 15 | 42 | 13 | 1.0 | 0.5 | 11.440 | 5.4300 | 0.081 | ||

| 6303 | 17 | 47 | 14 | 1.0 | 0.5 | 13.580 | 6.5800 | 0.109 | ||

| 6304 | 20 | 52 | 15 | 1.1 | 0.5 | 15.940 | 7.8800 | 0.142 | ||

| 63/22 | 22 | 56 | 16 | 1.1 | 0.5 | 18.390 | 9.2400 | 0.184 | ||

| 6305 | 25 | 62 | 17 | 1.1 | 0.5 | 22.380 | 11.490 | 0.219 | ||

| 63/28 | 28 | 68 | 18 | 1.1 | 0.5 | 24.990 | 13.880 | 0.284 | ||

| 6306 | 30 | 72 | 19 | 1.1 | 0.5 | 27.000 | 15.190 | 0.350 | ||

| 63/32 | 32 | 75 | 20 | 1.1 | 0.5 | 29.800 | 16.900 | 0.382 | ||

| 6307 | 35 | 80 | 21 | 1.5 | 0.5 | 33.360 | 19.210 | 0.454 | ||

| 6308 | 40 | 90 | 23 | 1.5 | 0.5 | 40.750 | 24.010 | 0.639 | ||

| 6309 | 45 | 100 | 25 | 1.5 | 0.5 | 52.860 | 31.830 | 0.836 | ||

| 6310 | 50 | 110 | 27 | 2.0 | 0.5 | 61.860 | 37.940 | 1.082 | ||

| 6311 | 55 | 120 | 29 | 2.0 | 0.5 | 71.570 | 44.760 | 1.368 | ||

| 6312 | 60 | 130 | 31 | 2.1 | 0.5 | 81.750 | 51.850 | 1.710 | ||

| 6313 | 65 | 140 | 33 | 2.1 | 0.5 | 93.870 | 60.440 | 2.097 | ||

| 6314 | 70 | 150 | 35 | 2.1 | 0.5 | 104.13 | 68.040 | 2.543 | ||

| 6315 | 75 | 160 | 37 | 2.1 | 0.5 | 113.42 | 76.800 | 3.046 | ||

| 6316 | 80 | 170 | 39 | 2.1 | 0.5 | 122.94 | 86.500 | 3.609 | ||

| 6317 | 85 | 180 | 41 | 3.0 | 0.5 | 132.67 | 96.580 | 4.284 | ||

| 6318 | 90 | 190 | 43 | 3.0 | 0.5 | 144.05 | 108.49 | 4.979 | ||

| 6319 | 95 | 200 | 45 | 3.0 | 0.5 | 156.66 | 121.98 | 5.740 | ||

| 6320 | 100 | 215 | 47 | 3.0 | 0.5 | 172.98 | 140.39 | 7.090 | ||